RECBest

RECBest - Recording and removal of the contaminant asbestos in the recycling of construction and demolition waste

Resource-efficient circular economy - construction and mineral material cycles (ReMin)

Building materials in buildings have a high recycling potential that is currently not being fully exploited due to a lack of processes. RECBest aims to develop reliable processes for the precise recording of pollutants in existing buildings, their remediation and demolition in order to obtain high-quality recycled material (RCM).

The project is being funded as part of the "Resource-efficient circular economy - construction and mineral material cycles (ReMin)" funding measure. "ReMin" is part of the BMBF research concept "Resource-efficient circular economy" and is aimed at resource-efficient construction and the extended use of mineral secondary raw materials from construction waste, slag, ash and mining residues.

Hazardous materials are only incompletely recognized before demolition

The recycling potential of building materials in buildings is often high, but is not fully exploited. One reason for this is the lack of methods that can be used to identify pollutants in existing buildings. As a result, when a building is demolished, for example, valuable recycling materials are mixed with the pollutants in such a way that they can no longer be separated afterwards. Contaminants can occur during further processing of the material in the material cycle. Professional landfilling of the contaminated building rubble also becomes more difficult.

Important steps for sustainable and optimal use of resources

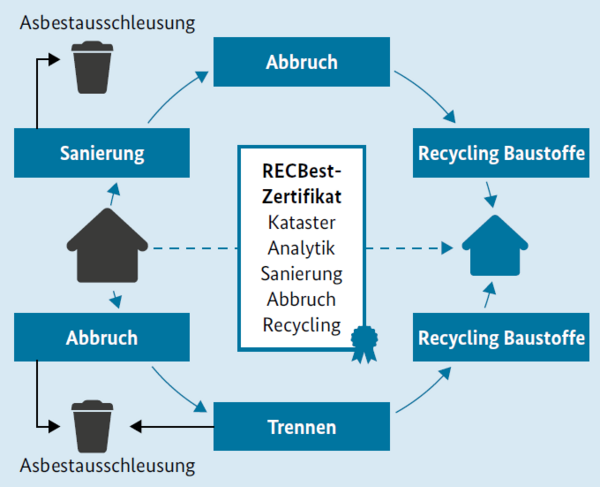

In the RECBest research project, solutions are being developed with which the high-quality recycling material can be identified and removed prior to the renovation or demolition of contaminated buildings. In the next step, this forms the basis for recycling the material. The result is a concept that ranges from collection, remediation and demolition to recycling and residual disposal. The research consortium is also developing a testing system to effectively ensure the quality of the recycled products.

The project will therefore fundamentally develop and test on-site inspection and sampling procedure concepts for mineral building materials contaminated with asbestos and other building pollutants in order to be able to analytically determine the total concentration of asbestos at low detection limits. In addition, separation methods for asbestos products - both in various states and from asbestos fibers per se - are being established in mass flows. The possibilities of the harmless fate of asbestos fiber components in recycled building materials or building products with the respective suitable use are also the subject of investigation. In the course of this, suitable monitoring of asbestos content in the building stock cycle as a whole is also to be determined. Furthermore, waste streams in the construction industry will be described beyond the currently practiced statistical survey, which will contribute to a better understanding of construction waste streams.

Greater safety and more reliability in the inspection of existing buildings

In future, an expert opinion is to be drawn up on the basis of an inspection at the start of a project, which will be available as a certificate for all stages of the process and can therefore be used beneficially. An examination that was previously only of use to specialist refurbishers now also forms the basis for the subsequent treatment and use of recycled materials. As the construction materials can be separated from impurities much more easily before demolition, the previous "downcycling" to road construction material and residual quantities can be upgraded to "upcycling".

Consortium of research and industry

The project is being coordinated by WESSLING GmbH. The company is also focusing on developing inspection and sampling procedures as well as measurement methods for reliably assessing the absence of asbestos in terms of materials, processing conditions and whereabouts. Kluge Sanierung GmbH will develop methods for removing asbestos from building structures prior to demolition. Buhck Umweltservices GmbH & Co. KG, together with the Department of Mechanical Process Engineering and Processing (FGMVTA) at the Technical University of Berlin, will focus on the treatment of waste with regard to waste characterization and categorization, separation processes, removal, recycling and disposal. The Department of Building Physics and Building Structures (FGBB) at the Technical University of Berlin carries out material flow analyses and evaluates the results according to life cycle assessment, economic and legal aspects.

Funding measure

Resource-efficient circular economy - construction and mineral material cycles (ReMin)

Project title

RECBest - Securing recycling material from asbestos - Collection and removal of asbestos as an impurity from construction and demolition waste to secure recycling material

Duration

01.03.2021-28.02.2023

Funding reference

033R268

Funding volume of the association

638,811 euros

Contact

Dr. Martin Hönig

Head of Asbestos / Expert Asbestos

WESSLING GmbH

Tel +49 234 6897 510

Fax +49 234 6897 222

Mobile +49 151 52 726 241

martin.hoenig@wessling.de

Project participants

TU Berlin; Kluge Sanierung GmbH; Buhck Umweltservices GmbH & Co. KG || Associated partners: REMEX GmbH; Bundesverband der Deutschen Entsorgungs-, Wasser- und Rohstoffwirtschaft e. V.; Bundesvereinigung Recycling- Baustoffe e. V.; Gesamtverband Schadstoffsanierung; Contrino-Consulting - Ingenieurbüro Bau und Umwelt

Data sheet

Download data sheet